Some of our competitors pride themselves in using the most modern, state-of the-art machines available for producing "historic" millwork. This does not make sense to Weston Millwork Company. For example, if you are trying to reproduce a Victorian door casing that was originally made in the 1870s, which machine will do the most authentic job? A modern, high-speed precision moulder, or the same machine that produced your original moulding? We agree with you! The original equipment would be the better choice.

While it is true that our old machines are not as "fast" at producing moulding as today's modern equipment is, there are several reasons that make the old machinery a superior choice. In addition to unexcelled authenticity, our machines are much more versatile and easy to set up for short-runs of moulding. This saves money in set-up costs. Additonally, Weston Millwork Company has the capability for grinding knives for an exact match. We also have hundreds of old, authentic moulding knives on hand.

Come, take a stroll with us through our working museum!

This planer is used on our outside planing mill for rough surfacing. As seen in the photo above, outfeed end of planer.

This machine clamps sash together quickly for pinning the mortise and tenon joints. It has a capacity of 5 ft. x 7 ft. The corner clamps swivel so the sash are self-squaring duing the clamping process.

This is one of several hollow-chisel mortisers WMCO uses for making authentic mortise and tenon joints. This machine was built in the l930s and is in the process of being restored. It quickly produces accurate mortises utilizing square hollow chisels that range in size from 1/4" to 1". Rectangular mortises are...

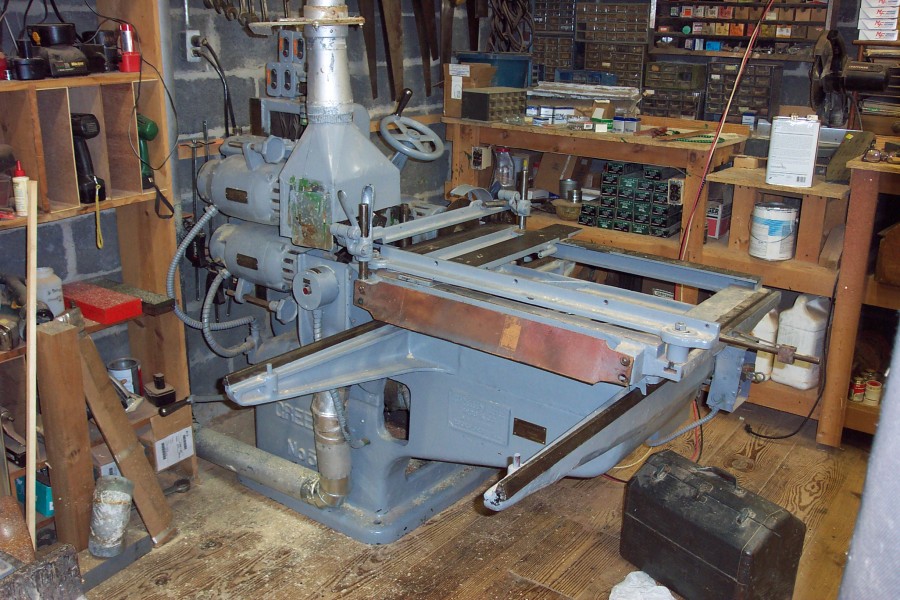

This is one of several tenoning machines in the shop for making tenons and coping rail ends for precision fitting mortise and tenon joints. The machine can be adjusted for any thickness of tenon and can tenon door rails up to 24" wide. As seen in the above photo, Greenlee...

Sash trimmers are a foot-operated machine used to cope the ends of sash bars that frame in at oblique angles. The angles are infinitely adjustable from 0-90 degrees. The machine is indispensable for sash that have diagonal bars such as the Corner Drugstore Sash Project in Leavenworth, Kansas. As seen...